Industry Overview

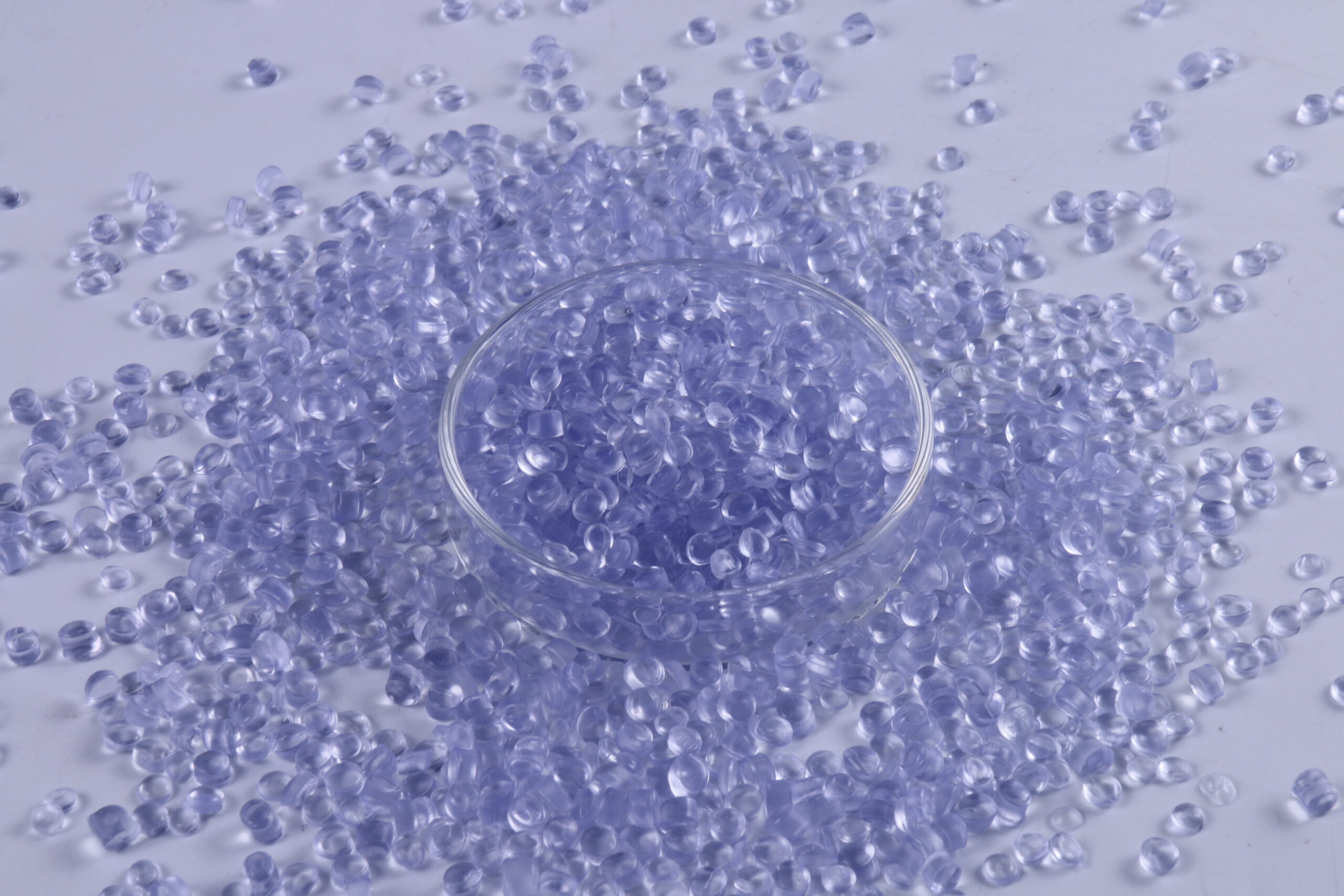

PVC foamed shoe sole granules are advanced polymer materials produced through specialized foaming technology. Specifically developed for manufacturing lightweight, comfortable, and elastic shoe soles, these granules play a critical role in modern footwear production. Over time, they have maintained a relatively high price point in the market — a reflection of their unique value and performance benefits.

Key Value: The Irreplaceability of PVC Foamed Granules

As a leading choice for shoe sole production, PVC foamed granules offer a combination of performance features that are difficult to replicate:

- Lightweight Excellence: The foaming process generates micro air cells within the material, drastically reducing density without compromising strength.

- Superior Comfort: Outstanding elasticity and cushioning absorb impact and relieve foot pressure.

- Enhanced Durability: Thanks to the inherent properties of PVC, soles made with these granules offer long-lasting wear resistance.

- Eco-Friendly Compliance: Fully compliant with global environmental standards such as REACH and RoHS, supporting sustainable and responsible manufacturing.

What Drives the Price: 8 Key Cost Components

- Premium Raw Materials

- Formulated with high-grade PVC resin and a balanced blend of additives (foaming agents, stabilizers, plasticizers, etc.).

- Quality inputs are essential for achieving top-level durability, comfort, and environmental performance.

- Price volatility in raw materials directly influences production costs.

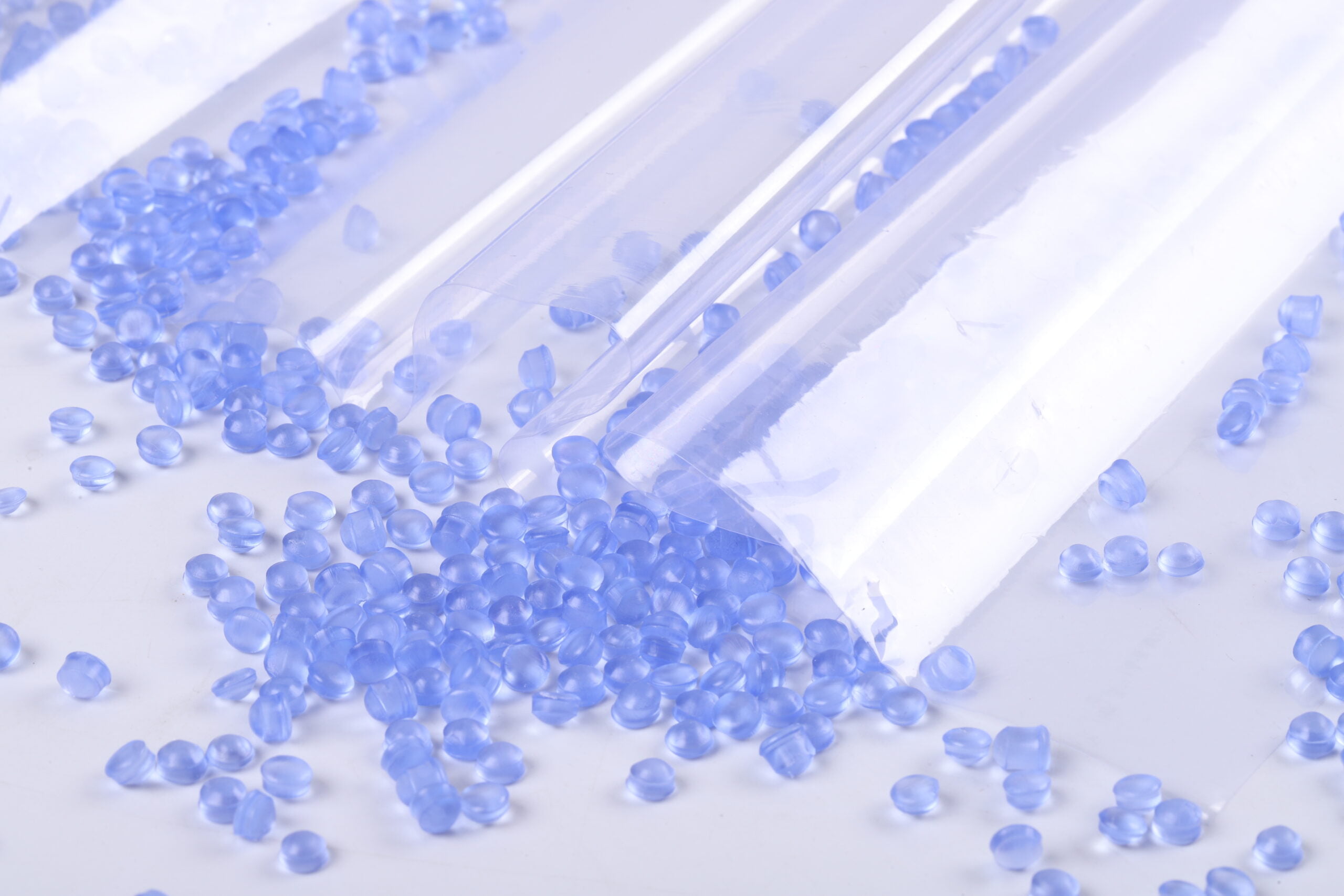

- Advanced Manufacturing Process

- Involves precise control over foaming, temperature, and material blending.

- Requires state-of-the-art equipment and highly skilled operation.

- Sophisticated processing and tight quality controls contribute to higher production expenses.

- Environmental Compliance & Certification

- Strict adherence to evolving global environmental regulations.

- Use of eco-friendly additives and materials to limit hazardous substances.

- Additional costs arise from compliance audits, certifications, and environmental management systems.

- Continuous R&D Investment

- Significant investment in improving foaming techniques and enhancing product performance.

- Ongoing development of next-generation materials that are lighter, stronger, and more efficient.

- These innovations are reflected in the product's value and pricing.

- Performance Enhancement Requirements

- Incorporation of specialty additives to improve properties such as abrasion resistance and flexibility.

- Rigorous quality assurance protocols throughout production.

- Meeting high-performance expectations naturally leads to increased costs.

- Customization Capabilities

- Tailorable density range (0.5–1.2 g/cm³) to meet specific product needs.

- Adjustable hardness (Shore A 45–80) to suit various footwear applications.

- Optional functional features such as anti-static or antibacterial additives.

- Customized solutions involve additional engineering and production efforts.

- Logistics & Transportation

- Larger product volume leads to higher shipping costs per unit.

- International logistics and handling requirements further impact overall cost.

- Some variants may require specific packaging or storage conditions.

- Supply & Demand Dynamics

- Market fluctuations can lead to price shifts based on demand and raw material availability.

- Limited capacity or raw material shortages can put upward pressure on prices.

- Industry-wide adjustments and seasonal cycles also play a role.

Long-Term Value: Justifying the Premium

While the initial cost may seem higher, PVC foamed granules deliver strong returns across the value chain: - Lower Transportation Costs

Lightweight properties allow for up to 20% more loading per container. - Reduced Returns & Warranty Claims

Durable soles mean fewer product failures and a 50% drop in return rates. - Stronger Market Positioning

Eco-certified materials open the door to premium product segments, increasing retail price potential by 15–25%.

Looking Ahead: Optimizing for Performance and Value

With ongoing advancements in processing technology and economies of scale, the cost-efficiency of PVC foamed shoe sole granules is expected to improve. These materials will continue to offer a compelling combination of quality, compliance, and customization — making them a smart investment for forward-thinking footwear manufacturers.