With the increasing demands for sealing performance in industries such as construction, automotive, and home appliances, PVC (polyvinyl chloride) sealing strips have become a key sealing material. The quality and performance of their raw material—PVC pellets—have attracted growing attention in the industry. As the fundamental material for manufacturing PVC sealing strips, the stable supply and high quality of PVC pellets directly affect the durability, sealing effectiveness, and service life of the sealing strips.

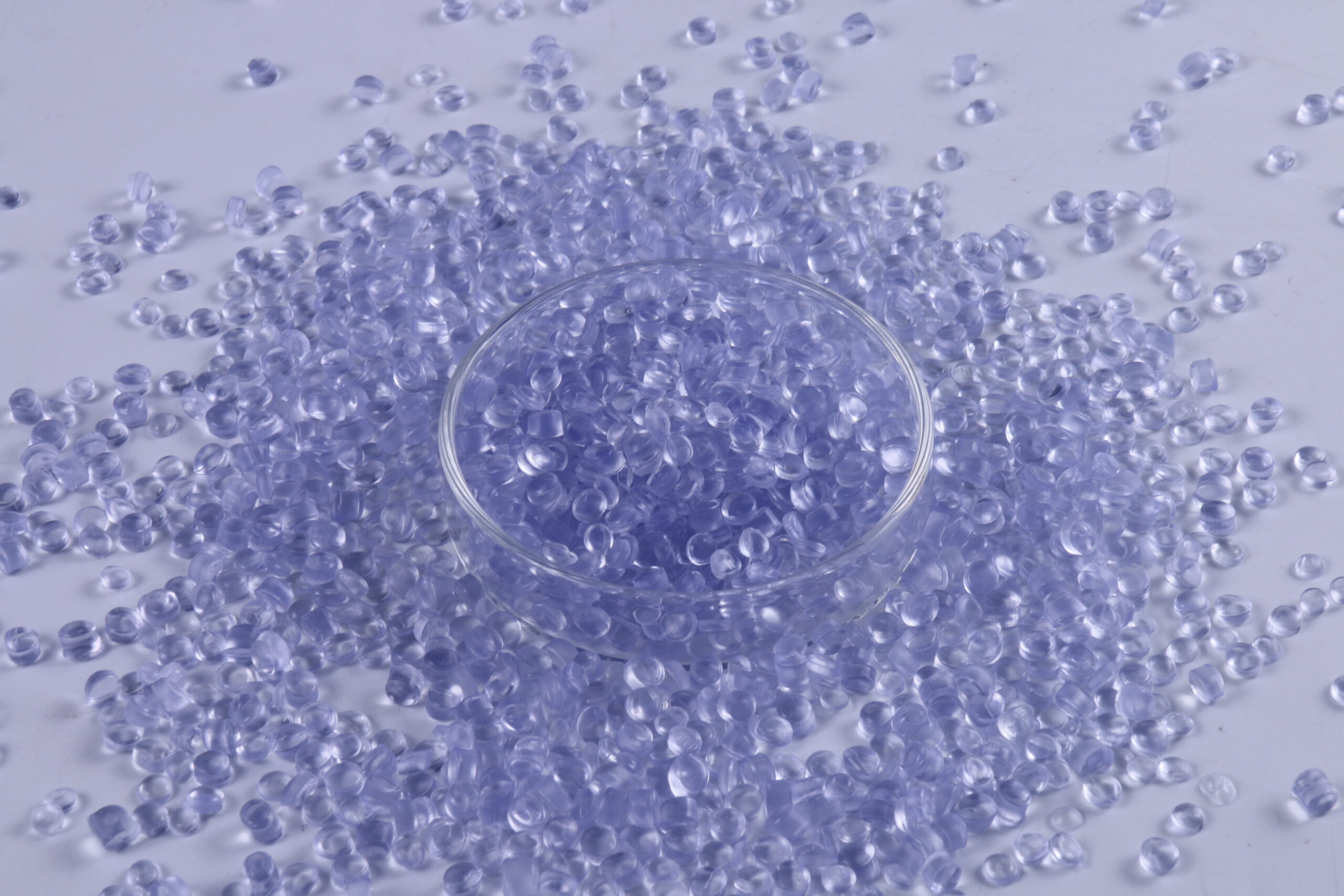

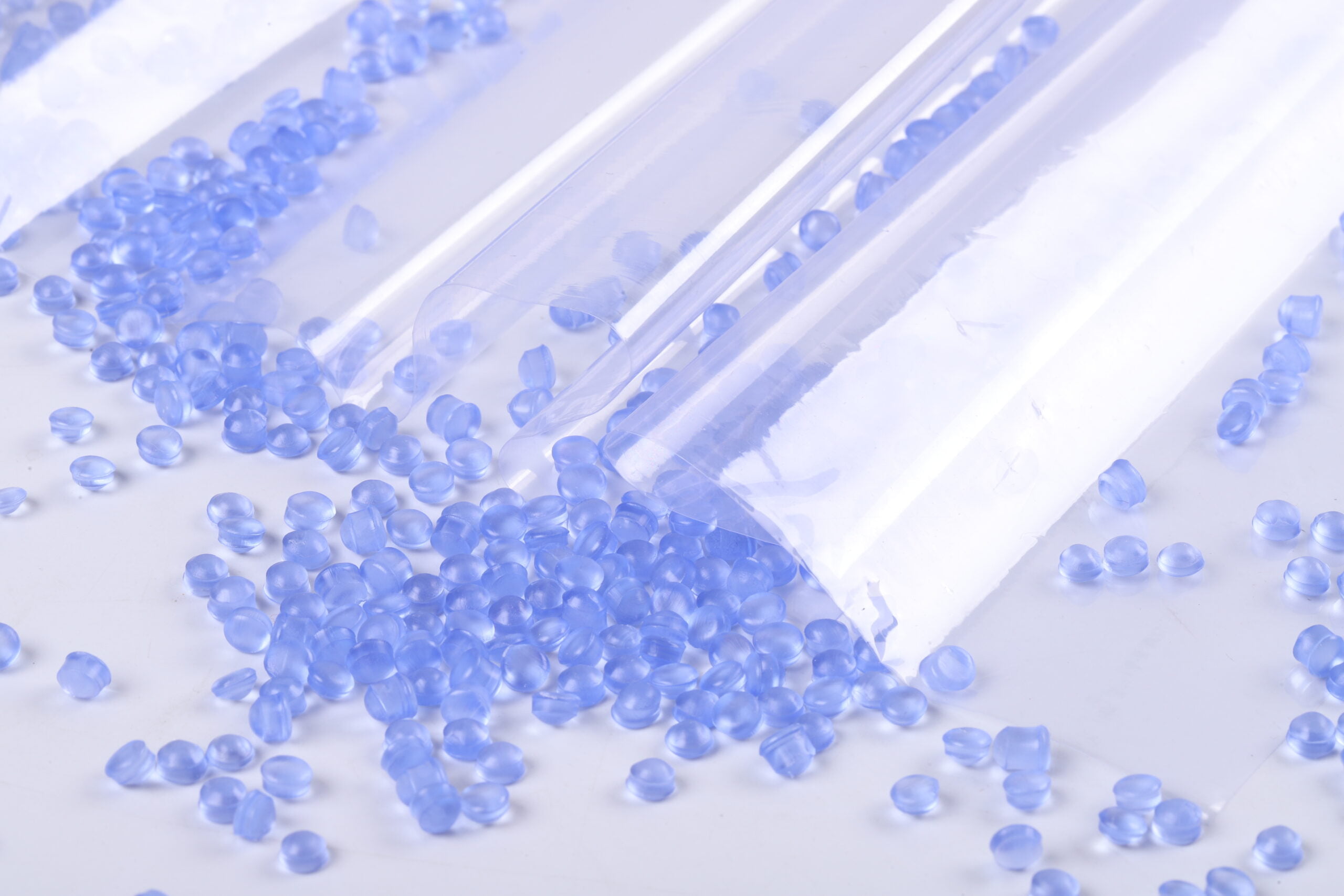

PVC pellets are plastic raw materials produced through processes such as batching, mixing, coloring, extrusion, and pelletizing, widely used in doors and windows, automotive seals, and household appliance seals. The quality of PVC pellets mainly depends on the type and amount of plasticizers, which determine the hardness and flexibility of the PVC. Soft PVC pellets contain more plasticizers, providing sealing strips with excellent softness and sealing performance, while rigid PVC is suitable for applications requiring stronger structural support.

In recent years, with the rapid growth of the automotive sealing strip market in China, the demand for both the quantity and quality of PVC sealing strip raw materials has continued to rise. Data shows that in 2020, China’s PVC production reached 20.74 million tons, an increase of 3.1%, providing solid raw material support for the sealing strip industry. The market demand for high-performance PVC pellets has driven manufacturers to continuously optimize formulations and processes, enhancing material tensile strength, cold resistance, and environmental friendliness to meet the stringent requirements of various application environments.

Industry experts point out that high-quality PVC pellets should possess good chemical stability, electrical insulation, and weather resistance. During processing, the use of plasticizers and stabilizers must be strictly controlled to avoid harmful residues, ensuring the safety and environmental compliance of the finished sealing strips. Moreover, customized PVC pellet solutions tailored to different customer needs have become a trend, promoting diversification and upgrading of sealing strip products.

With technological advances and market demand upgrades, the PVC sealing strip pellet raw material industry is embracing new development opportunities. Continuously improving product quality, strengthening environmental regulations, and innovating applications will drive the entire sealing strip supply chain to a higher level, providing more reliable material support for energy-efficient buildings, automotive sealing, and home appliance sealing sectors.