描述

Specification

PVC (Polyvinyl Chloride) compounds are widely used in the manufacturing of ball valves, particularly in applications that require resistance to corrosive substances. These materials exhibit several key characteristics that make them suitable for various industrial applications, especially within the chemical industry.

General Characteristics

1.Chemical Resistance:

PVC is highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This property ensures that PVC ball valves maintain their integrity and performance even when exposed to aggressive substances, making them suitable for use in chemical processing and wastewater treatment applications.

2.Durability:

The robust nature of PVC contributes to the durability of ball valves. PVC ball valves can withstand high pressure and are designed to endure mechanical stress over extended periods without degradation24. This durability is essential for maintaining operational reliability in industrial settings.

3.Thermal Stability:

PVC exhibits excellent thermal stability, allowing it to function effectively across a wide temperature range. This characteristic is particularly important for applications that involve fluctuating temperatures or require resistance to thermal expansion and contraction.

4.Low Friction:

The low coefficient of friction inherent in PVC allows for smooth operation of the valve mechanism. This property facilitates the easy rotation of the ball within the valve body, contributing to efficient flow control and reduced wear on components.

5.Impact Strength:

High impact strength is another notable feature of PVC compounds used in ball valves. This characteristic helps prevent damage from physical impacts or stress during installation and operation.

6.Dimensional Stability:

PVC maintains its shape and size under varying environmental conditions, which is crucial for ensuring consistent performance and reliable sealing capabilities over time.

7.Cost-Effectiveness:

PVC is a cost-effective material compared to metals and other plastics, making it an attractive option for manufacturers looking to balance quality with affordability.

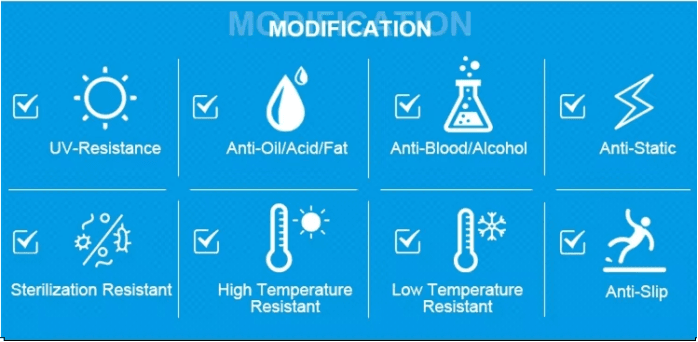

8.Additives for Enhanced Properties:

Manufacturers often incorporate additives such as plasticizers, stabilizers, and pigments into PVC compounds to enhance specific properties like flexibility, UV resistance, and coloration. These modifications allow for customization based on application requirements.

Modification

The modification of PVC compounds for ball valves significantly enhances their functionality and longevity in demanding applications. By focusing on improving chemical resistance, mechanical properties, and incorporating innovative designs, manufacturers can produce high-performance valves that meet the stringent requirements of various industries. Selecting the right PVC compound tailored to specific operational conditions is essential for optimizing system performance and ensuring reliability over time.