Overview of Rigid PVC Compounds for Extrusion

Rigid PVC (Polyvinyl Chloride) compounds are widely used in various applications, particularly in the extrusion process, due to their excellent mechanical properties and versatility. These compounds are created by combining PVC resin with specific additives that enhance their performance characteristics, such as rigidity, durability, and color.

Characteristics of Rigid PVC Compounds

- Durability: Rigid PVC is known for its long lifespan, often ranging from 10 to 100 years, making it suitable for a variety of applications including construction and automotive components[1].

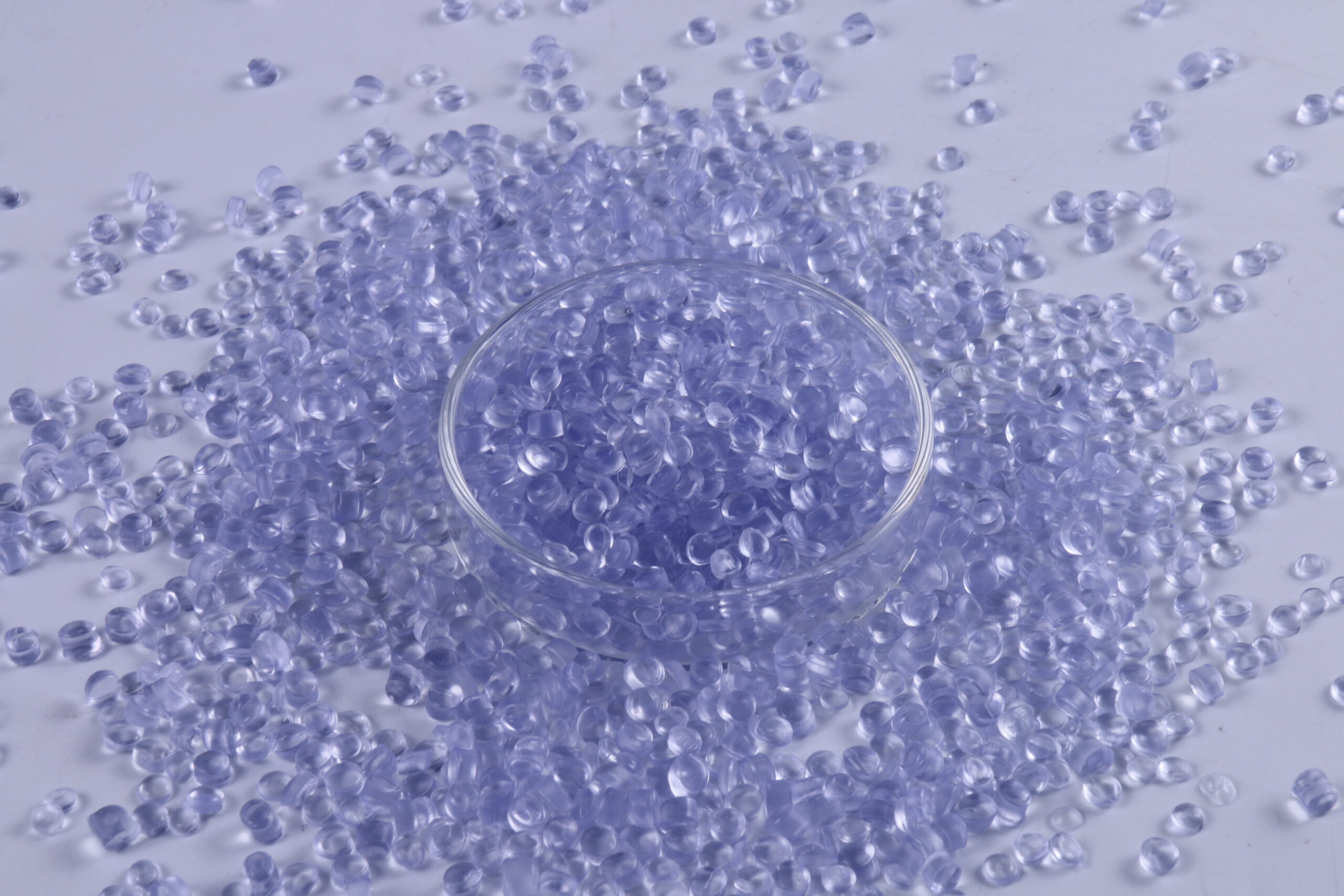

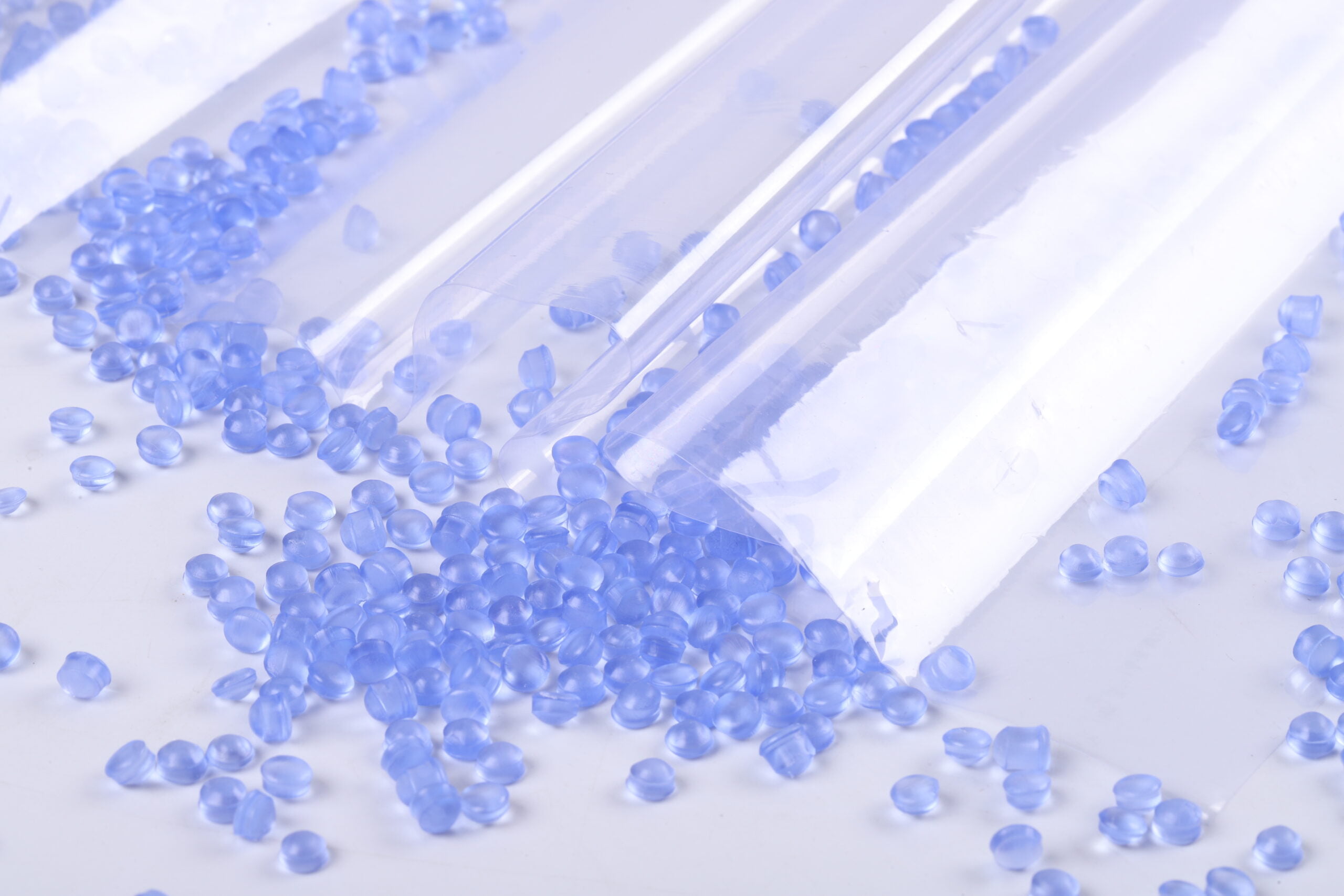

- Form: These compounds are typically supplied in the form of granules or pellets, which can be easily processed through extrusion or injection molding methods[1][3].

- Customizability: The addition of various additives allows manufacturers to tailor the properties of rigid PVC compounds to meet specific requirements, such as fire resistance or color matching[2][4].

Applications

Rigid PVC compounds are utilized in numerous sectors, including:

- Building and Construction: Used for window profiles, pipes, and fittings due to their strength and resistance to environmental factors[3][4].

- Automotive: Employed in components like electrical conduits and interior fittings due to their durability and lightweight nature[3].

- Medical: Certain formulations are used in medical devices because they can be made antimicrobial and safe for healthcare applications[3][4].

Conclusion

Rigid PVC granules are a crucial component in many industries due to their adaptability, durability, and cost-effectiveness. With ongoing advancements in compounding technology, manufacturers continue to enhance the performance characteristics of these materials, ensuring they meet the evolving needs of various applications.