PVC coated wire ropes have become a staple in various industries due to their unique combination of strength, flexibility, and resistance to environmental factors. This article delves into the materials used, production processes, characteristics, and common applications of PVC coated wire ropes.

Materials Used

PVC coated wire ropes are primarily made from the following materials:

-

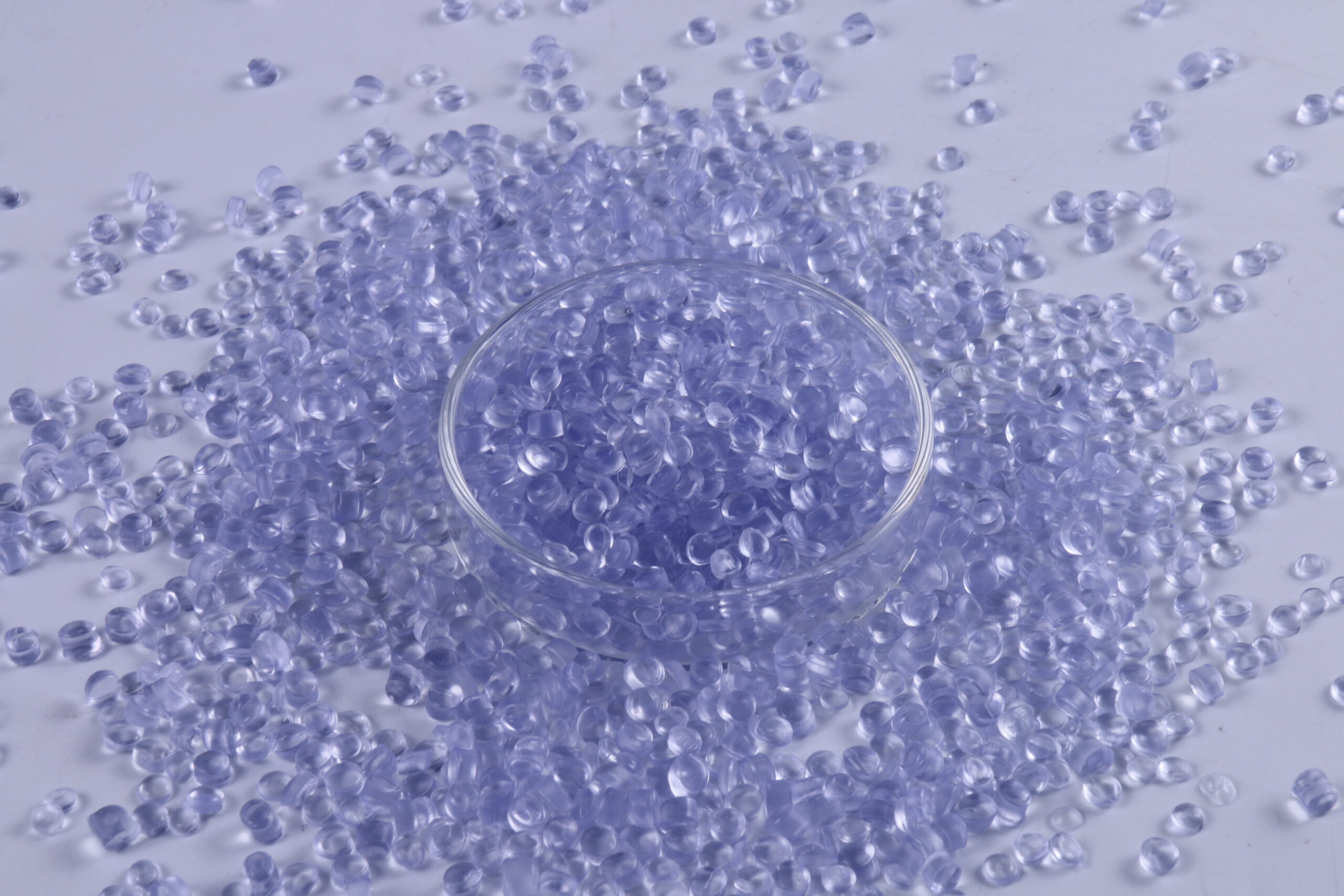

PVC Plastic: Provides excellent insulation and weather resistance.

-

PE (Polyethylene): Enhances flexibility and durability.

-

Nylon: Offers additional strength and abrasion resistance.

Production Process

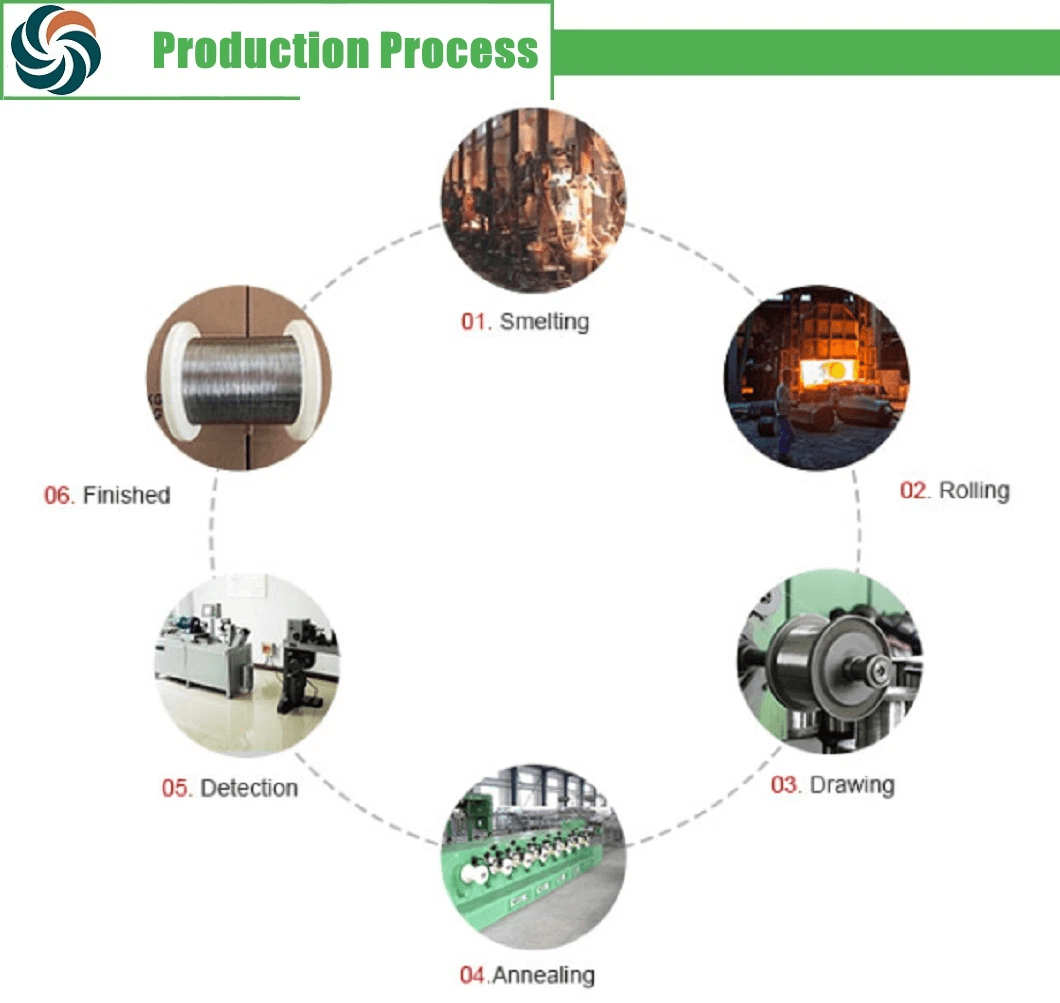

The production of PVC coated wire ropes involves several key steps:

-

Wire Rope Manufacturing: The process begins with the creation of the wire rope itself, typically structured in configurations such as 7×7 or 7×19.

-

Coating Application: The wire ropes are then coated with PVC, which enhances their corrosion resistance and provides a protective barrier against environmental factors.

-

Quality Control: Rigorous testing is conducted to ensure that the coated wire ropes meet industry standards for strength and durability.

Key Characteristics

PVC coated wire ropes are known for several advantageous characteristics:

-

Cost-Effective: They offer a low-cost solution for various applications without compromising quality.

-

Good Elasticity and Insulation: The PVC coating provides excellent insulation properties, making them suitable for electrical applications.

-

High Temperature and Abrasion Resistance: These ropes can withstand high temperatures and are resistant to wear and tear, ensuring longevity.

-

Tensile Strength: They possess strong tensile strength, making them ideal for heavy-duty applications.

-

Density: The density of PVC coated wire ropes ranges from 1.22 to 1.35 g/cm³.

-

Hardness: The hardness is measured between Shore A 80-85, indicating their robustness.

Color Options

PVC coated wire ropes are available in a variety of colors, including:

- Dark Green

- Black

- White

- Grass Green

- Blue

These color options not only enhance aesthetics but also help in identifying different applications or uses.

Modification Requirements

To meet specific application needs, PVC coated wire ropes can be modified for:

- Abrasion Resistance

- Anti-Static Properties

- UV Resistance

Common Applications

PVC coated wire ropes are widely used in various applications, including:

-

Clotheslines: Durable and weather-resistant, ideal for outdoor use.

-

Greenhouse Frameworks: Provides structural support while resisting environmental wear.

-

Gabion Nets: Used in erosion control and landscaping.

-

Protective Fencing: Offers safety and security in various settings.

Conclusion

PVC coated wire ropes are an essential component in many industries due to their versatility, durability, and cost-effectiveness. As demand for high-quality, resilient materials continues to grow, PVC coated wire ropes are poised to play an even more significant role in future applications.

Citations:

[1] https://www.youtube.com/watch?v=jntHHV10Evo

[2] https://www.unionrope.com/Portals/0/Documents/Technical/Wire-Rope-Basics/wire-rope-handbook.pdf

[3] https://www.youtube.com/watch?v=VBs-MKI-Xx8

[4] https://www.shenwei-steelwirerope.com/info/the-production-process-of-plastic-coated-wire-98301202.html

[5] https://stainless-wire.co/a-deep-dive-into-the-techniques-and-technologymanufacturing-process-of-special-steel-wire-ropes/

[6] https://stainless-wire.co/in-depth-look-at-the-manufacturing-process-of-ss-wire-rope/

[7] https://totalropesolutions.co.uk/product/bespoke-pvc-coated/

[8] https://www.essentialsupplies.co.uk/black-galvanised-wire-rope-3mm-7-x-7-drum-100m-pvc-coated.html