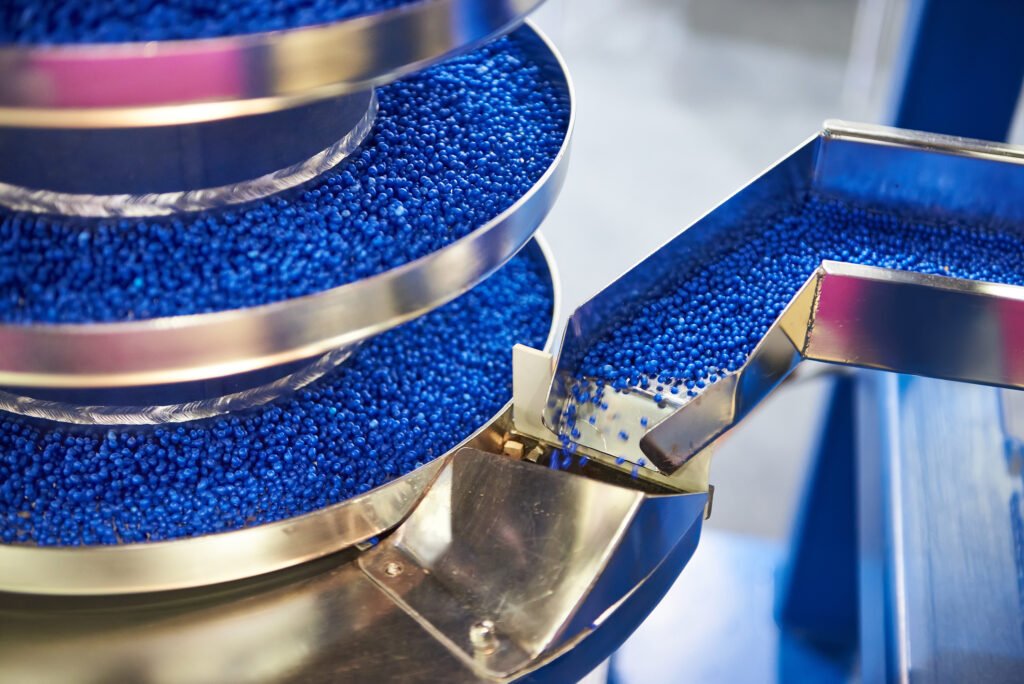

YOHO PVC Raw Material Factory

Making high quality PVC pellets for a sustainable future to meet the needs of different partners worldwide.

Customization

We specialize in crafting custom PVC products designed to meet your unique specifications. With cutting-edge technology and meticulous attention to detail, we deliver high-quality, eco-friendly solutions that elevate your business to the next level.

Provide professional laboratory testing services for you.

Our Lab Services

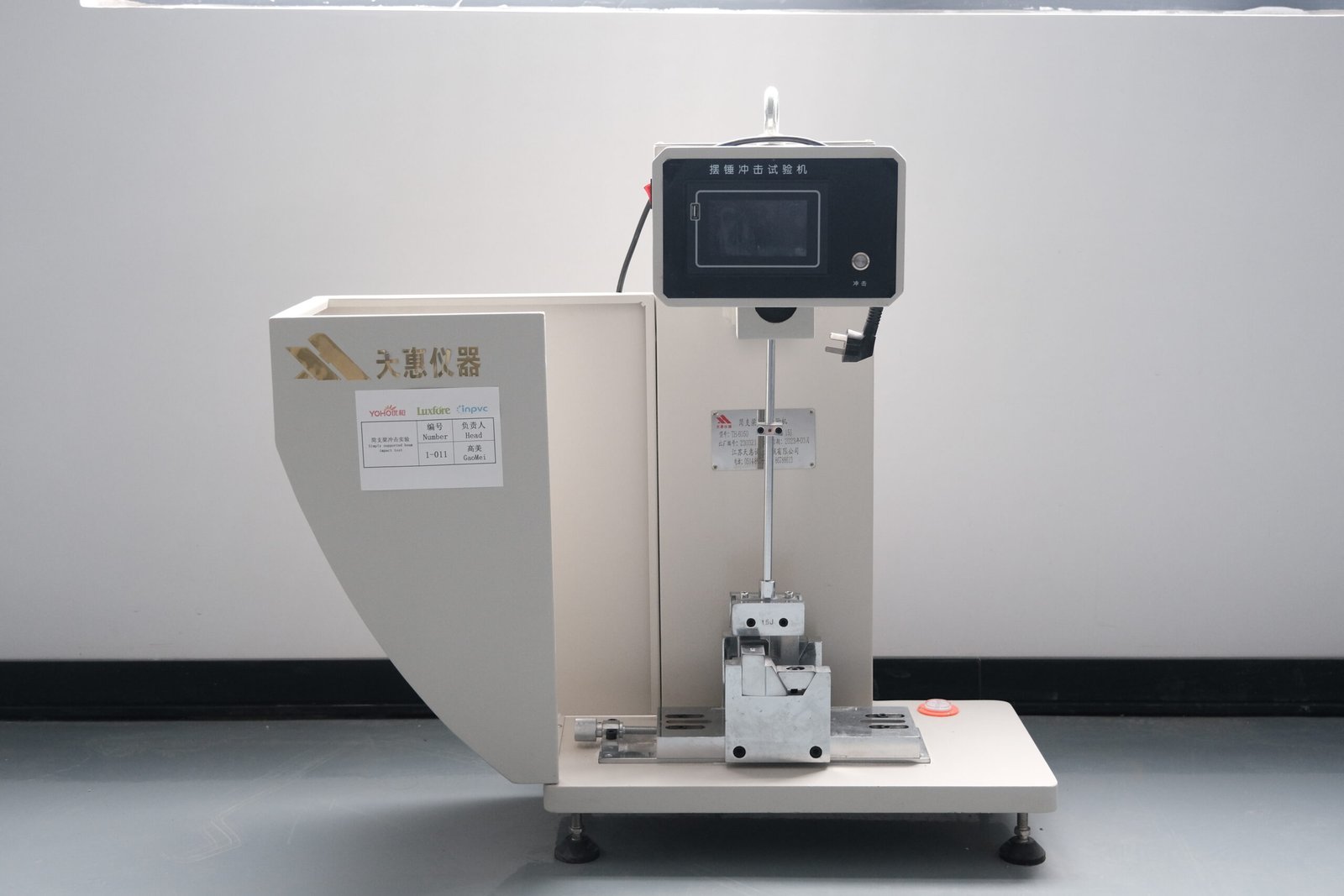

Simple Beam Impact Testing Machine

The simple beam impact testing machine is a device used to measure the impact resistance of materials, typically metals and plastics. It operates by releasing a pendulum to strike a notched specimen supported as a simple beam, simulating real-world impact conditions.

Electronic universal test instrument

An Electronic Universal Test Instrument is a versatile device used for evaluating the mechanical properties of materials, such as tensile strength, compression, and flexural properties.

oil bath pan

An oil bath pan is a device used to heat samples uniformly in a laboratory setting, using oil as the heating medium.

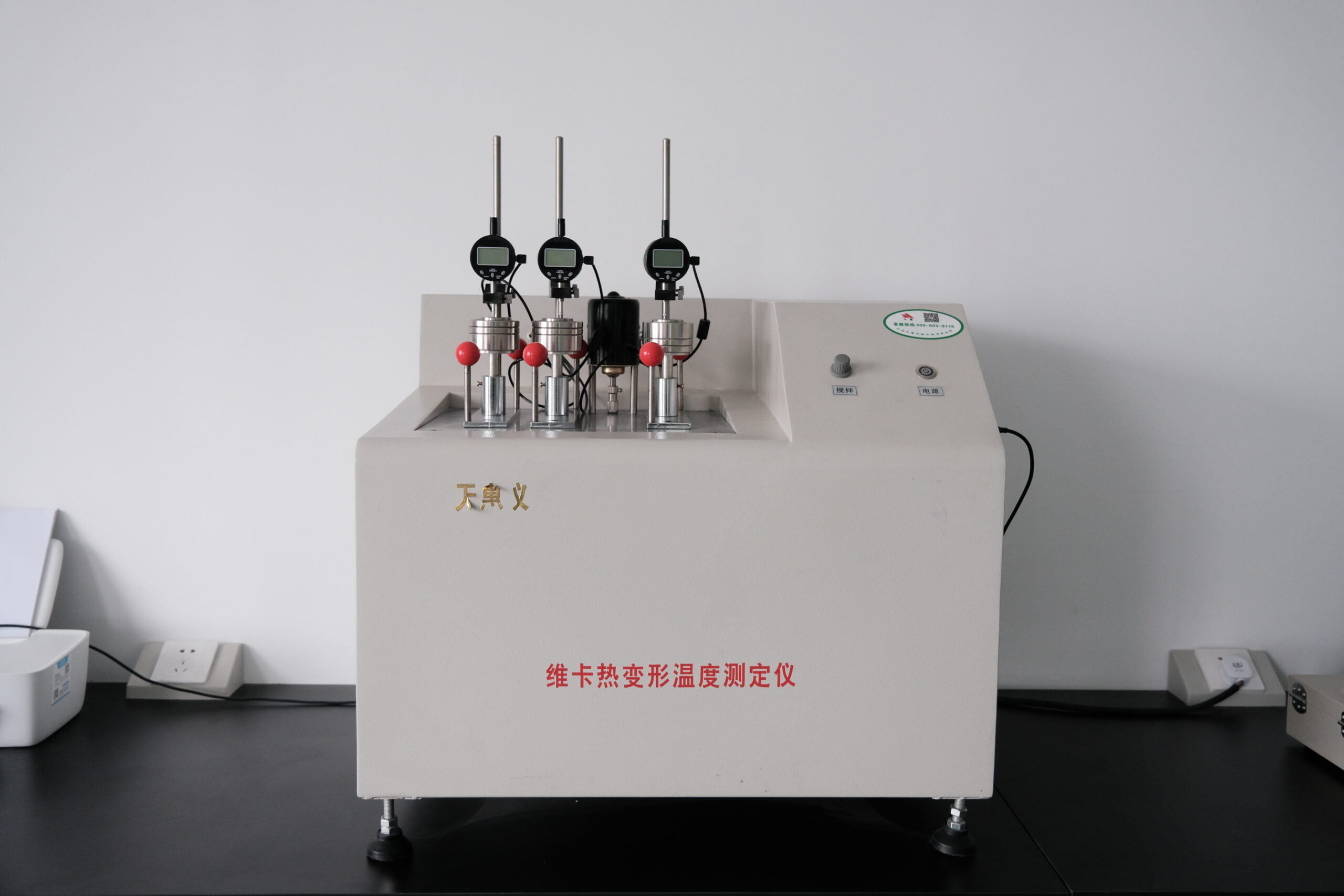

vicat softening point instrument

The Vicat softening point instrument measures the temperature at which a plastic sample deforms under a specified load.

Production Automation

The factory showcases its commitment to innovation through advanced production automation systems. By integrating cutting-edge robotics, AI-driven data analysis, and state-of-the-art automated control systems, they streamline every step of the manufacturing process. This ensures precision, consistency, and exceptional product quality while significantly reducing labor costs and production time.

YOHO PVC’s automated systems enable real-time monitoring and optimization, allowing them to swiftly adapt to changing demands and maintain the highest standards of efficiency. With production automation, YOHO PVC is not only enhancing productivity but also paving the way for a sustainable and intelligent manufacturing future.

Production Security

YOHO PVC places paramount importance on production security, implementing rigorous safety protocols and advanced monitoring systems throughout their manufacturing process. By leveraging real-time data analysis and automated safety controls, they ensure a secure and reliable production environment. This proactive approach minimizes risks, prevents disruptions, and guarantees the consistent delivery of high-quality products. YOHO PVC’s dedication to production security not only protects their workforce but also upholds their commitment to excellence and customer satisfaction.

What Advantages

Our advanced automation ensures efficient production and reduced costs. Rigorous safety protocols guarantee consistent and reliable performance. Choose YOHO PVC for superior quality, customized solutions, operational efficiency, and unwavering reliability.